The Best Products

Product Pocessing Information

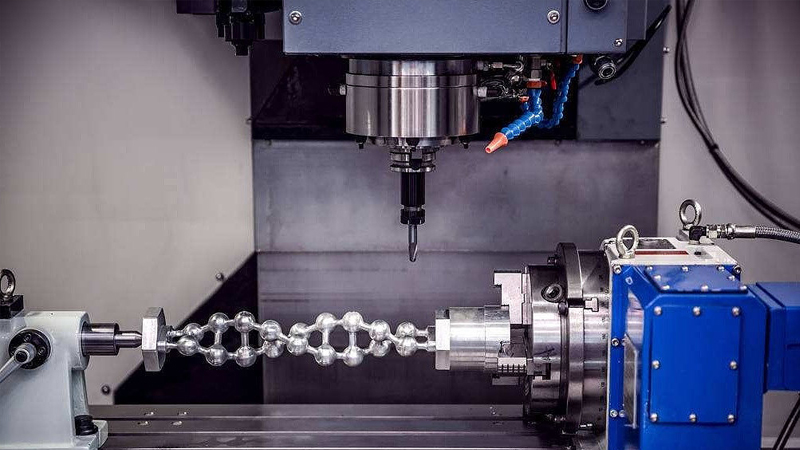

Processing accuracy: ± 0.01mm, maximum accuracy ± 0.001mm, concentricity © 0.005mm; Parallelism 0.01mm; Verticality L0.01mm, multiple 850CNC machining machines in progress

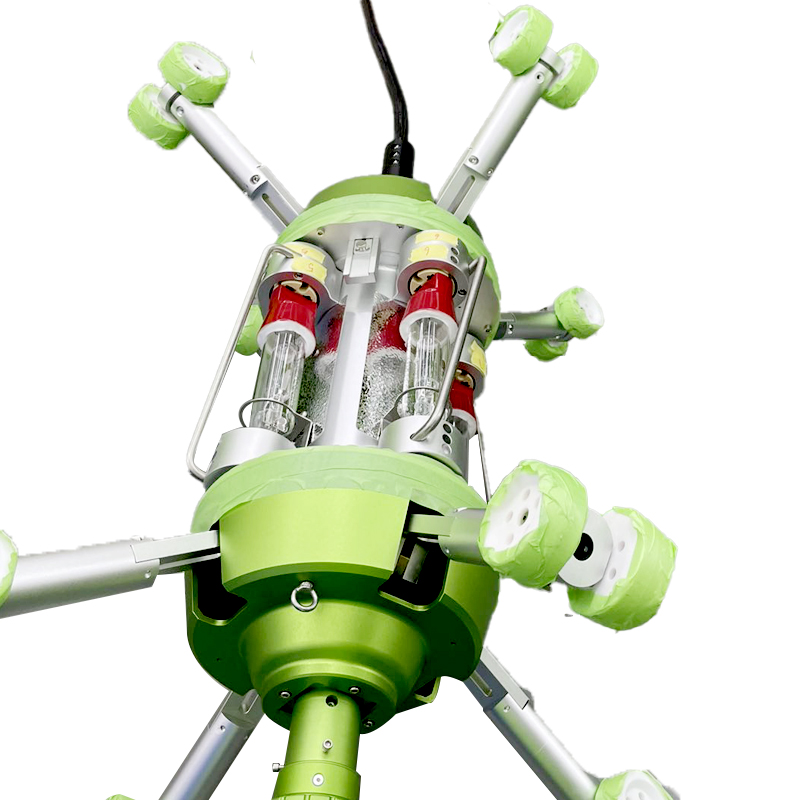

Production equipment: Heart carving machine, drilling and tapping machine, five axis car sharpening composite; Wire cutting, mirror EDM optical grinding, CNC lathe washing, composite machining, flat grinding, punching machine, gear hobbing, etc.

Standing gun/lying sickle, batch one-stop production, with discounted prices.

Processing characteristics: Process according to the drawing (sample).

Processing mode: anime, inside/outside micrometer, tool microscope, universal angle ruler, height ruler, stop/go gauge, etc.

Testing equipment: a, meets the requirements of the drawing; b. Meet customer's routine requirements; c. Meet normal shipping standards. Stable product quality, excellent service quality, and customer satisfaction.

Shipping standards\Quality indicators:

Commonly processed raw materials: bustard steel, imported materials, SKD11, SKD6L SUS505/304/516/516L A5052, AL6061, AL6063, AL7075, Ly12,65Mn, Cr12, 40C, Mo, 45 #, Q275, ST12.03S235KSS1994-04, AISI12L14.Y15, Electrical, POM Saigang, Nylon, Iron,fluorolone, acrylic, etc.

Common surface treatments include anodizing, etching, ironing, galvanizing (black zinc), blackening, electropolishing, passivation, titanium plating, powder spraying, electrophoresis, etc.

Common heat treatments: vacuum quenching, salt bath nitriding, nitriding, carburizing, carbon nitrogen co carburizing, high-frequency firing, immersion firing, quenching and tempering, etc.

Previous: No More