The Best Products

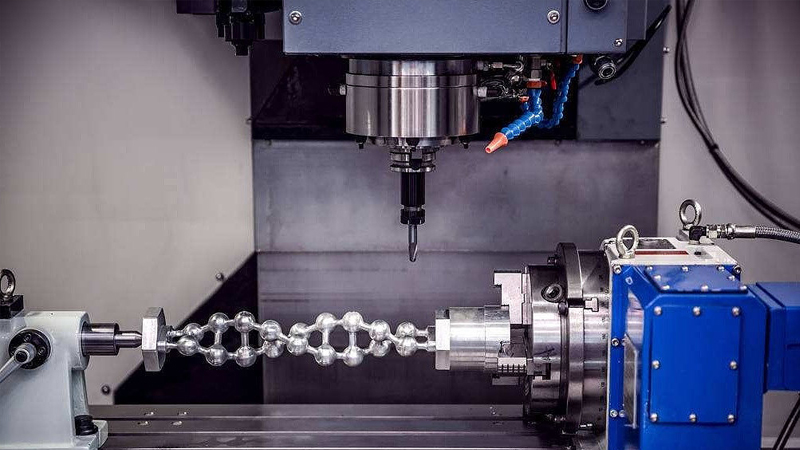

Knowledge Of Mechanical Component Manufacturing

Production Program: The production volume and schedule plan of the products that should be produced during the planning period.

Production batch: refers to the quantity of the same product or part that is inputted or outputted at once.

Workpiece clamping: positioning and tightening.

Process: The part of a process in which a worker (or a group) continuously processes one (or several) workpieces on a machine tool (or workplace).

Step: The part of the process that needs to be completed continuously on the same workstation while maintaining the same machining surface, cutting speed, feed rate, and tool for different surface treatments.

Workstation: In order to complete a certain process, after clamping the workpiece, the workpiece (or assembly unit) and the movable part of the fixture or equipment occupy each position relative to the fixed part of the tool or equipment. A machine with multiple main molds and multiple punching dies is called a multi workstation.

Installation: If the workpiece needs to be clamped several times in a process, the part of the process completed under each clamping becomes one installation.

Cutting tool: The work step completed by cutting a cutting tool on a machining surface in one go.

Production process and technological process

(1) Production process: The production process of mechanical products is the entire process of transforming raw materials into finished products. It includes: transportation and storage of raw materials, production preparation work, rough manufacturing, cold and hot processing of parts, assembly, inspection, painting, and packaging of components and products.

(2) Process: The process in which the shape, size, relative position, and properties of the production object can be changed during the production process, making it a finished or semi-finished product is called a process

Previous: CNC Lathe Machining Accuracy

Next: No More